Sun control paint for spraying on glass

Sun control paint white for painting on glass

Sun control paint for spraying on synthetic glass

-

Flat glass films, Sun control paint

Sun control paint for spraying on glass

52,50 € – 205,50 €0 out of 5incl. VAT

zzgl. Versandkosten

Select options This product has multiple variants. The options may be chosen on the product pageSchnellansicht -

Flat glass films, Sun control paint

Sun control paint white for painting on glass

52,50 € – 205,50 €6.00 out of 5incl. VAT

zzgl. Versandkosten

Select options This product has multiple variants. The options may be chosen on the product pageSchnellansicht -

Flat glass films, Film for synthetic glass, Sun control paint

Sun control paint for spraying on synthetic glass

52,50 € – 195,50 €0 out of 5incl. VAT

zzgl. Versandkosten

Select options This product has multiple variants. The options may be chosen on the product pageSchnellansicht

Shopping guide for sun control paints

Glazing can put strain on people and machines, if it lets solar energy through unprotected. Sun control paints offer a practical solution for this. Read this guide to find out how sun control paints are used.

Table of contents

Sun control paint: The solution for uneven surfaces

The sun control paint is a milk glass white special paint that is applied to the exterior side of glass panes or plastic glazing.

Sun protection for glass panes and plastic

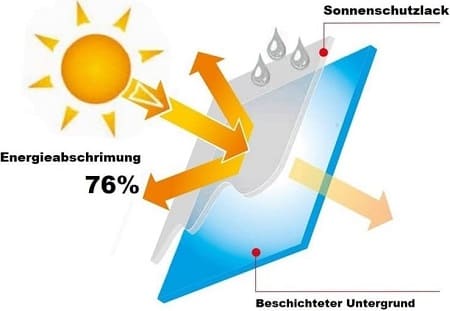

The sun control paint provides excellent protection against unpleasant heat, glare and UV radiation on summer days. With around 76% sun protection, 90% glare reduction and 99% UV filter, rooms get pleasantly cool and glare-free. The milk glass white color of the special paint ensures pleasant brightness and daylight permeability.

The sun control paint ensures permanent sun protection on glass and plastic panels

Ideal for rough and uneven surfaces

The big advantage of the sun control paint is that – unlike sun control films – it can also be installed to glass and plastic surfaces that have a rough or uneven surface. Due to its special composition, the high-performance paint is quick-drying and weather-resistant.

Roof glazing is a typical application area

The special paint is therefore ideal for coating the exterior side facing the weather. This includes roof glazing, skylights, double-wall panels, wire glazing, shed glazing, skylight domes, cathedral and Profilit glazing. Typical areas of application are industrial buildings, production rooms and greenhouses.

Material: High adhesiveness & abrasion resistance

The sun control paint is made of high-quality composite materials – a prerequisite for its high adhesiveness and long service life.

Paint pigments ensure milk glass optics

The paint is based on solvents and binding agents. The volatile solvents evaporate during drying. They leave the non-volatile components as a solid film on the surface. The binding agents are responsible for producing a homogeneous mass. The pigments are important for the milk glass white color and the high light transmission.

Epoxy resins guarantee high adhesiveness

The epoxy resins used ensure adhesiveness and abrasion resistance on the substrate. The best prerequisite for a particularly long service life. This is because the paint forms a permanent bond with the coated surface and – unlike a film – cannot be removed without leaving residue.

💡 Tip: The paint cannot be completely removed after it has been applied. We therefore recommend testing the paint on an old pane or area that is no longer needed before use.

Variants: Paint for glass and plastic panels

For coating glass surfaces, the paint is available either for brushing or spraying. For coating plastic panels such as polyvinyl chloride (PVC), polystyrene (PS), polycarbonate panels (PC), Plexiglas, Macrolon and Lexan, the paint is available for spraying. Coating is not possible for plastics such as polyethylene and mixtures of polyamides.

💡 Tip: For plastic glazing that is equipped with a scratch protection layer, we recommend carrying out tests on the adhesion of the paint before painting.

Application: With a paint roller or a spray gun

The milk glass white special paint is applied to the exterior side of glass panes and plastic glazing with either a paint roller or a spray gun.

Spray gun for uniformly results

If you want to save time and quickly cover large areas with new heat protection paint, you should use a spray gun. Spray systems are ideal for achieving the most homogeneous, regular surface possible because they guarantee an uniformly application of the paint. If the spray system has a quantity control, blobs, paint drops and splashes are avoided. The atomized paint droplets reach every corner, so that even hard-to-reach areas can be coated cleanly.

Paint rollers also suitable for small areas

With paint, an even and gap-free application is important. This goal can also be achieved with a paint roller or a brush. When painting with a brush or roller, however, the object’s own brush or roller structure is also applied – everyone knows the small notches in the paint caused by the brush hairs. However, this does not matter when coating glass surfaces that are at a great height. Because of the great distance, you cannot see the brush strokes.

💡 Tip: The paint can be used for up to 8 hours after opening. Therefore, only mix as much paint as can be coated on the same day.

Do not apply below 5° Celsius

The surface must be carefully cleaned with a cleaner and water before coating. The paint is then mixed and applied to the completely dry surface. The ambient temperature should not be below 5° Celsius. The coating must be protected from rain, dew or frost during the drying time, otherwise the hardening will be impaired. The drying time is about 1-4 hours depending on the ambient temperature.

Online shopping: Paint delivery in 1-3 working days

We deliver the paint in practical 1.0 kg or 5.0 kg containers. You can order the heat protection paint inexpensively online from us. It will be with you in 1-3 working days. Pay conveniently by invoice, credit card, PayPal, instant bank transfer or advance payment. You can also order by email to service@vonkuester.de. If you have any questions, just call our hotline on +49 8152-8474.